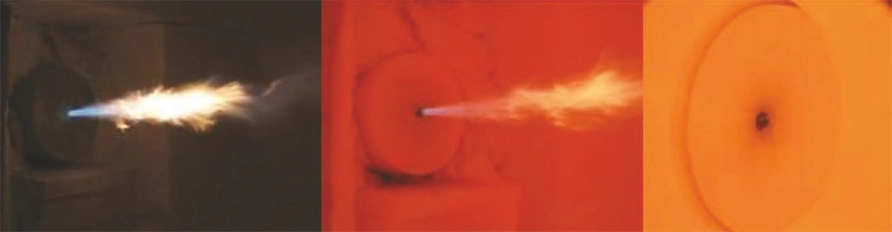

Why Oxy-Fuel Combustion? Nitrogen molecules form air don’t absorb or radiate energy well, which results in 50% of energy input being wasted, going right up the flue. Oxy-fuel nearly doubles the heat transferred compared to Air-fuel. Our OPTIFLAME Lade Pre-heating Technology employs these advantages to maximize the energy transfer and to reduce the total heating time. This improves not only the heating rate, but also the way how the ladle heats through and thus reduces temperature shock on the refractory and maximize the refractory lifetime. Holding the temperature inside a ladle consumes much less energy as well, reducing CO₂ at the same time. Reducing the heating time allows a reduction of pre-heating stations and to better utilize your assets. Oxyfuel burners with in-furnace flue gas recirculation, originally developed in the late 1970s, have evolved to simulate traditional air flames with a high-momentum, low-temperature flame. The concept advanced in the late 1980s, approaching the conditions of a "homogeneous reactor" where furnace temperatures and species concentrations are uniform.

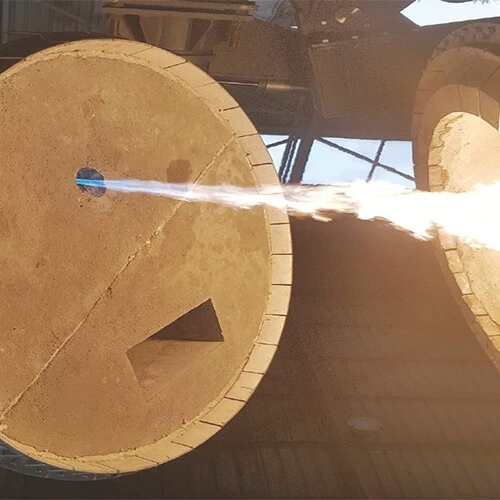

Rotary Aluminum Burner

Rotary fuel, equipped with OptiFlame Combustion Technology, excel in recycling a wide range of materials, including aluminum, lead, zinc, copper, and tin. Whether it's scrap, bulk, crushed materials, shot chips, or slag oxides, our technology can handle it all. In addition, they are also capable of melting ingots and foundry weights.

- Oxy Fuel as Hybrid Oxy/Air-Fuel Burner

- Lowest energy consumption

- Highest Productivity

- Metal yield