Nitrogen molecules from air don’t absorb or radiate energy well, which results in ~50% of energy input to a melter being wasted, going right up the flue. Oxy-fuel nearly doubles the heat transferred to the bath compared to Air-fuel, but pure oxygen also raises OpEx, has a higher flame temperature, creates NOx, and can lower yield. While the performance of other combustion systems suffer with reduced operating performance when firing outside the design settings, our OPTIflame burner fires optimally at all firing levels, thanks to the dynamic action of our fully automated flame shape control device, within the burner itself. This is essential to deliver the heat where it needs to be regardless of firing rate. For new and existing furnaces, our OPTIflame burners fire 10 kW up to 20 MW, tailor-made to each melter. Performance is guaranteed: O2/ton, NG/ton, kg/m2/hr with realistic ROI’s of 6-12 months.

Optiflame Meltling Technology

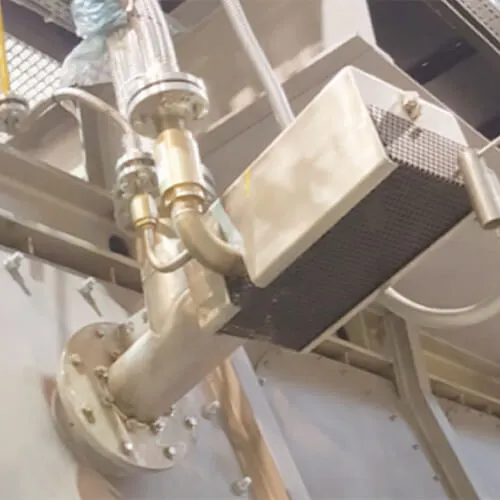

OPTIflame Melting burner has been designed to fire natural gas, hydrogen, or both to combine the combustion benefits of lower OpEx Air-fuel and higher productivity Oxy-fuel in one burner. The OPTIflame burner employs both radiative and convective energies as heat transfer mechanisms, maximizing homogeneity of the bath, increasing productivity, while maintaining/improving yield. We provide our customers the most economical, most reliable, and most predictable turn down of any burner on the world market.

- Higher Combustion Efficiency

- Lowest Oxygen Participation

- Reduced Exhaust Gas Volume

- Ultra-Low NOx

- Lowest fuel Consumption

- Highest Melting Rate

- Low CO₂ Generation

- Low Maintenance